Shell Eco-Marathon puts Ultra-Energy-Efficient Student Team Vehicles to the Test

Earlier this month we were lucky enough to attend the Shell Eco-Marathon – which was held at the Queen Elizabeth Olympic Park on Friday 6th July. This annual event attracts over 1,200 students from academic establishments all over the world. It has been founded in order to encourage greater interest in STEM subjects, by getting teams of students to design and develop their own vehicles and compete against one another. To win, the competing vehicle has to cover the course while expending the least amount of energy.

One of the major contenders looking for a podium place this year was the team from the Technical University of Munich (TUM), in Bavaria. TUFast Eco have been involved in this competition for the last 6 years and in 2017 managed to pick up second place in their category. The vehicle muc018 that the team has created for this latest enduring racetrack encounter relies on the incorporation of Harwin connectivity components.

There are three different vehicle classes that participate in the Shell Eco-Marathon: battery-powered electric vehicles, ones using hydrogen fuel cells, and ones that are based on some form of internal combustion engine. Also there are two different vehicle specifications – UrbanConcept (where the race cars are quite similar to conventional road vehicles) and more rudimentary three-wheeled prototypes. The bar has certainly been set high – for example, in the UrbanConcept race, participating teams’ vehicles have to be able to travel a staggering 1000km on just a single liter of gasoline, while averaging a speed of 25km/h.

If that wasn’t difficult enough, there were further technical challenges to this year’s race that the TUFast Eco team had to deal with. Firstly, their vehicle had to support fully autonomous operation, with the ability to traverse a specially built course without any driver intervention. Secondly, they needed to have a modular construction, where it was easy to replace the constituent modules.

The TUM students and post-graduates involved in the team all come from very different backgrounds. Some are electrical or mechanical engineers, others are mathematicians, physicists, computer scientists and even business specialists. In total, the interdisciplinary team comprised 44 people, 20 of whom came to London to play a part in the race itself. The team were able to take the vehicle from the drawing board to a point where it was fully functional and ready to compete in less than 10 months.

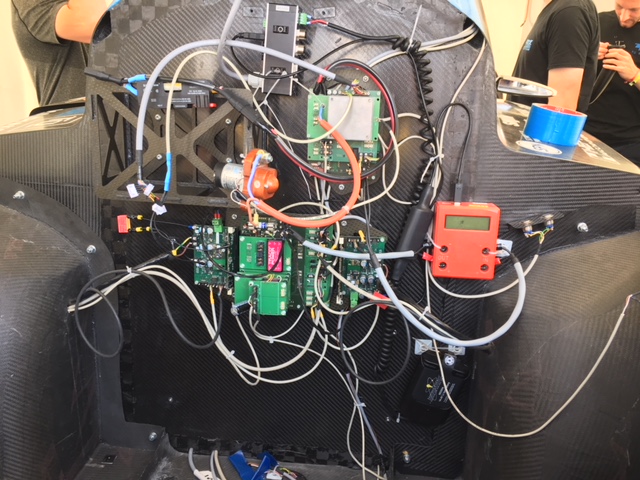

One of the issues that the TUFast Eco team had struggled with in the past was making the electrical system reliable enough. So, with this year’s vehicle, much greater focus was placed onto this aspect. This is where Harwin’s expertise came into play. The decision was made for our connector products to be used in the communications, electrics and powertrain elements of the vehicle. The components specified came from the award-winning Datamate series. These have a rugged but lightweight construction that is highly optimized for resource-constrained system designs. This means that they prove to be of great value in situations where robustness is mandated, while at the same time the weight needs to kept to a minimum and there is only limited available space.

The Datamate connectors are widely utilized in auto sport – from high performance F1 cars to electric race vehicles. Their use meant that the continued integrity of the system interconnections could be maintained and there was no risk of power or data loss. This also kept in line with the TUFast Eco team’s objective of ensuring that the overall weight of the vehicle was as low as possible, as well as with the modular arrangement of the new vehicle design.

In a close-fought battle, the TUFast Eco team managed to accomplish a good run in the UrbanConcept race for electric vehicles, with fuel economy figures of approximately 112.8km/kWh.

They then went on to compete in the autonomous vehicle competition, which required the vehicle to undertake a series of complex maneuvers – including negotiating its way around the numerous obstacles placed onto the course, automatic braking as close to a barrier as possible (without crashing into it) and parking.

The team secured second place in the autonomous vehicle competition and took home the ‘technical design’ award off the racetrack. Overall the team have made great progress this year; motivated by their successes, work has already begun on the design of their next generation model for 2019!

Discover more connectors and hardware for Motorsport and electric vehicles.

Uh oh, it looks like you are using an outdated browser version.

Some functions may not work as expected on Harwin.com in your current browser. For the best experience, more security and speed, we recommend updating your browser to the latest version.

(if you are using Internet Explorer, we recommend switching to an alternative browser.)

Still having issue? Contact [email protected] for help.