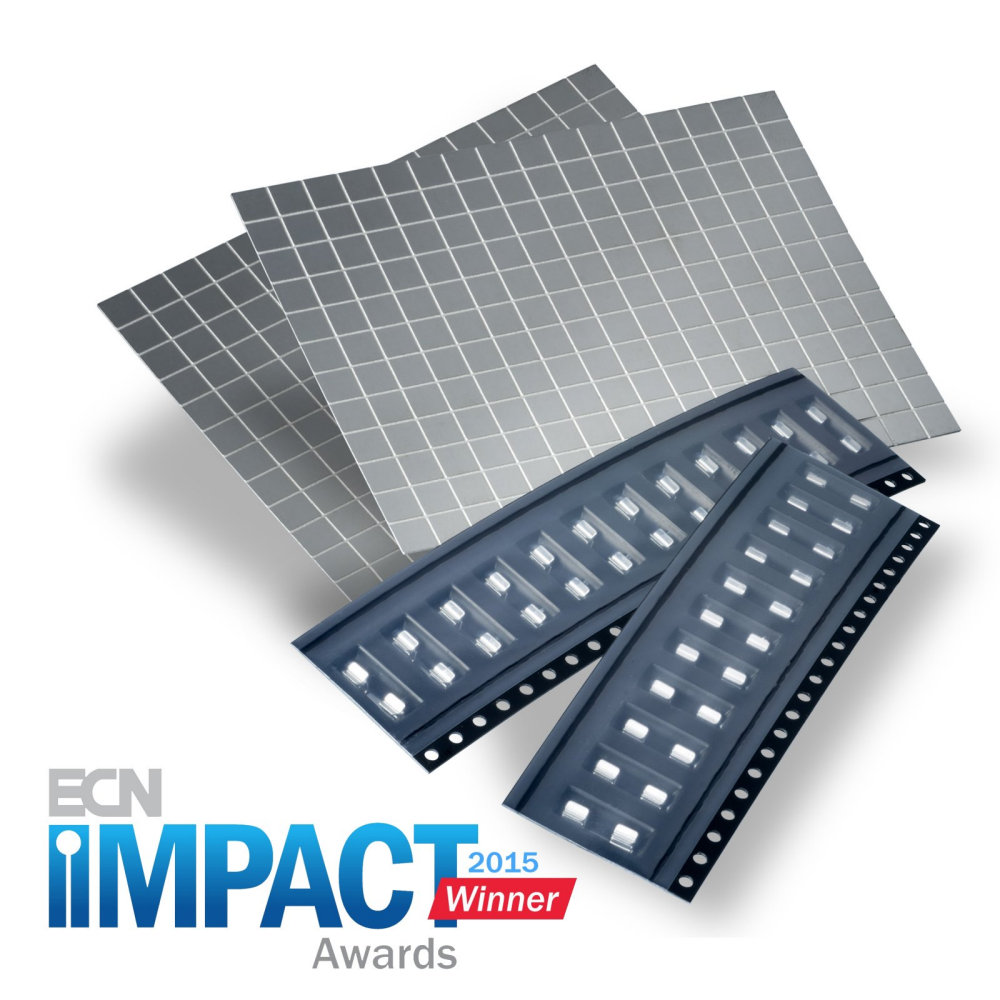

RFI Shield Cans

Nickel Silver cans in a simple 5-sided shape. Designed for use with Harwin’s Shield Can Clips for board-level shielding, no soldering is required on the can for easy fitting. Contact our Experts for assistance with customized shield can sizes.